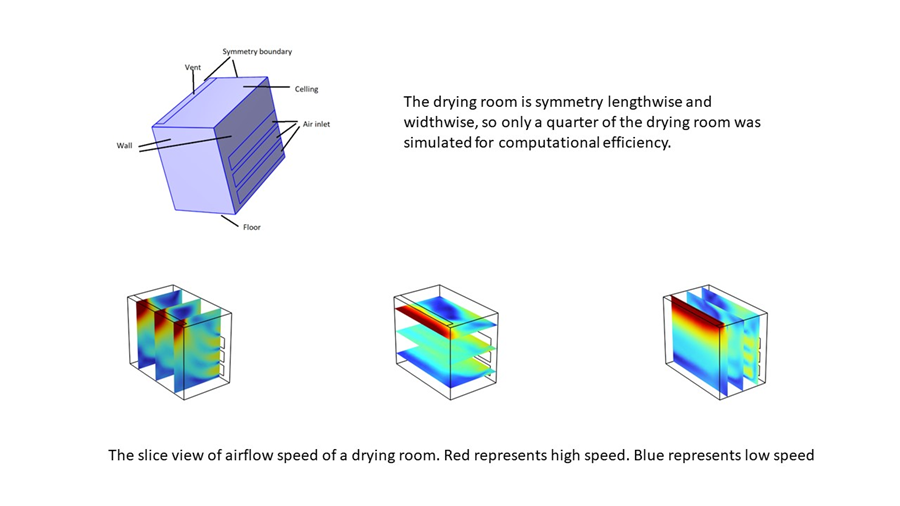

It is commonly believed, even by HVAC professionals, that symmetrical placement of air inlets and outlets will lead to uniform airflow in a drying room. However, is this true? To investigate, we analyzed the airflow in a room with three rows of air diffusers symmetrically positioned on both lengthwise walls at the lower part and one row of vents located at the center of the ceiling. The air speed at the inlet was set at 0.5 m/s.

Using simulations, we generated thermal maps displaying airflow speed in various directions within a quarter of the drying room. The colors on the map indicate airflow speed, with red representing high speed and blue indicating low speed.

Our results reveal that the airflow is not uniform, with numerous areas exhibiting low airflow speed. These areas are known as wet spots and pose a higher risk of excessive microbial growth.

At Robust Solutions Pro, we conduct simulations of all growing and drying rooms to identify any environmental outliers. Our simulations also explore various what-if scenarios, allowing you to select the best solution that meets your business requirements, whether it be low operating costs, low capital costs, high homogeneity, or other factors.